Following the reveal of the all-new Mizuno Alpha III, we caught up with Tsuyoshi Tomita from the brand’s Global Footwear Product HQ to find out all about the revolutionary new boot.

Mizuno have never needed to shout. It's just not in the brand's nature. Instead, they speak quietly through shape, feel and an almost obsessive attention to detail. In short, they let their craftsmanship do the talking. The release of the Alpha III is no different, although it marks a significant moment for the brand, not just as the latest evolution of its speed silo, but as a statement of intent. A full-knit upper enters the conversation for the first time, emotion is engineered into motion, and fit remains the axis around which everything else turns. And I'm not joking when I say that, having worn this boot, the highest compliment that I can pay it is that it's as comfortable as a Morelia. Sure, it's a marked step away from traditional leather, but don't think for one second that it's a step away from the brand's signature craftsmanship.

To understand how the balance between comfort and performance was struck, we sat down with Tsuyoshi Tomita from Mizuno’s Global Footwear Product HQ, one of the key figures behind the Alpha III’s development. From the philosophy of the Engineered Fit Last NEO to the challenge of shaping a one-piece knit upper, Tomita offers a rare insight into the thinking, testing and craftsmanship that define Mizuno Football. This is the story of a boot designed not to chase speed trends, but to refine them — guided by heritage, driven by fit, and motivated by more.

How did the Alpha III begin for you? Was there a moment or insight that sparked the direction of this next generation of Mizuno speed?

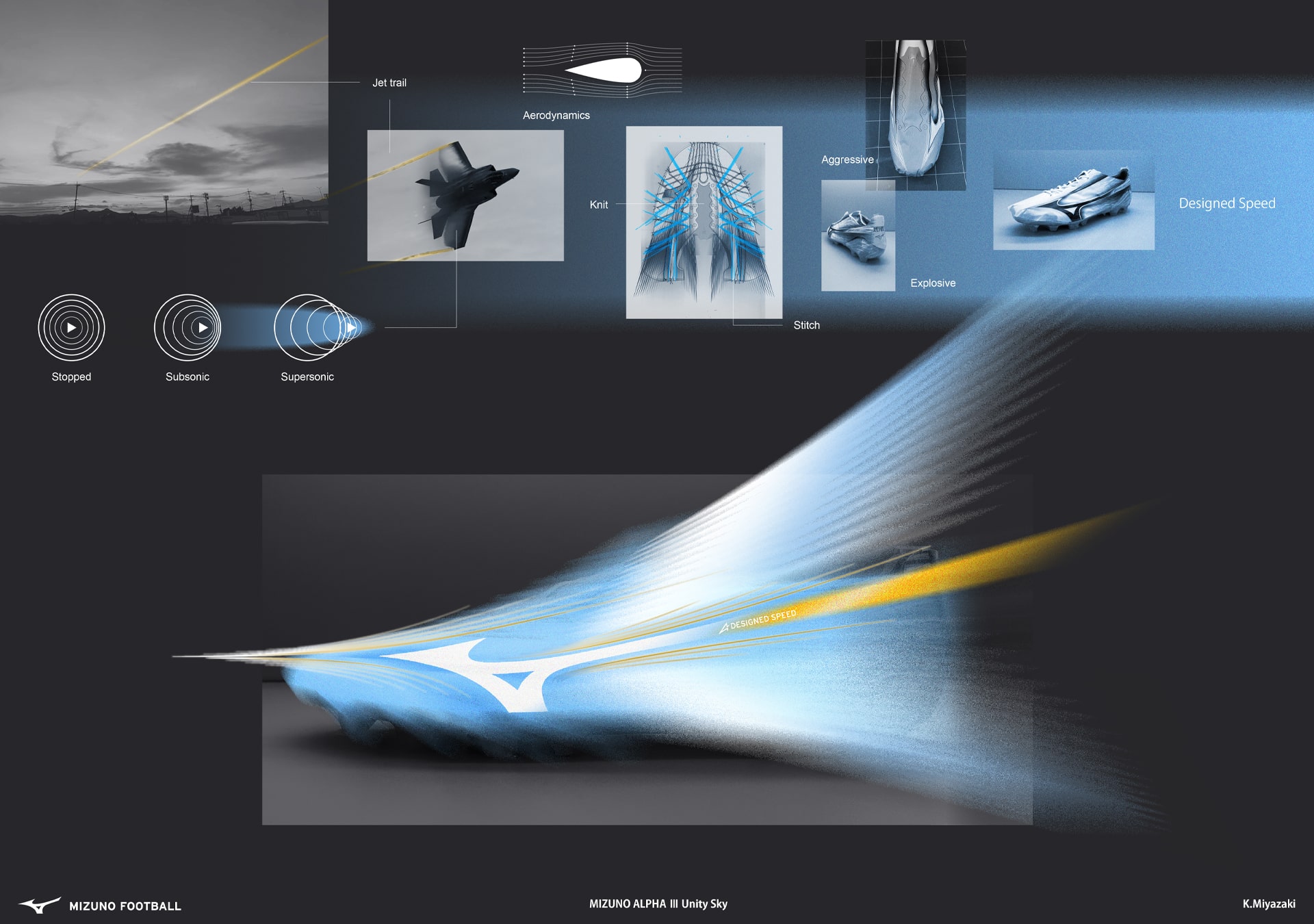

The MIZUNO ALPHA story began in 2022, when we introduced the fastest football boot in Mizuno’s history, designed with an uncompromising focus on speed. In 2025, ALPHA II followed, pushing fit to an entirely new level. Just one year later, that evolution continues with ALPHA III. While the core philosophy remains unchanged, the third generation takes “Designed for Speed. Refined by Fit.” even further, delivering what we believe is the ultimate Mizuno-style fitting experience.

The boot sits within the “Motivated by More” Pack, a campaign built around the invisible energy that drives athletes forward. How did that idea influence the earliest conversations around the Alpha III’s identity?

The “Motivated by More” concept is rooted in the idea that an athlete’s greatest rival is themselves. One of the defining themes behind ALPHA III was surpassing what we had done before. The launch colourway, Pulse Black, reflects this mindset. Black represents determination and focus, while white on the RunBird line symbolises tension and possibility. Blue and red graphic accents express inner and outer passion, visualising that invisible drive.

Mizuno has always had a more understated, craftsmanship-led voice in football. With the Alpha III introducing your first full knit upper in the silo, what did you want this material shift to say about where Mizuno is heading?

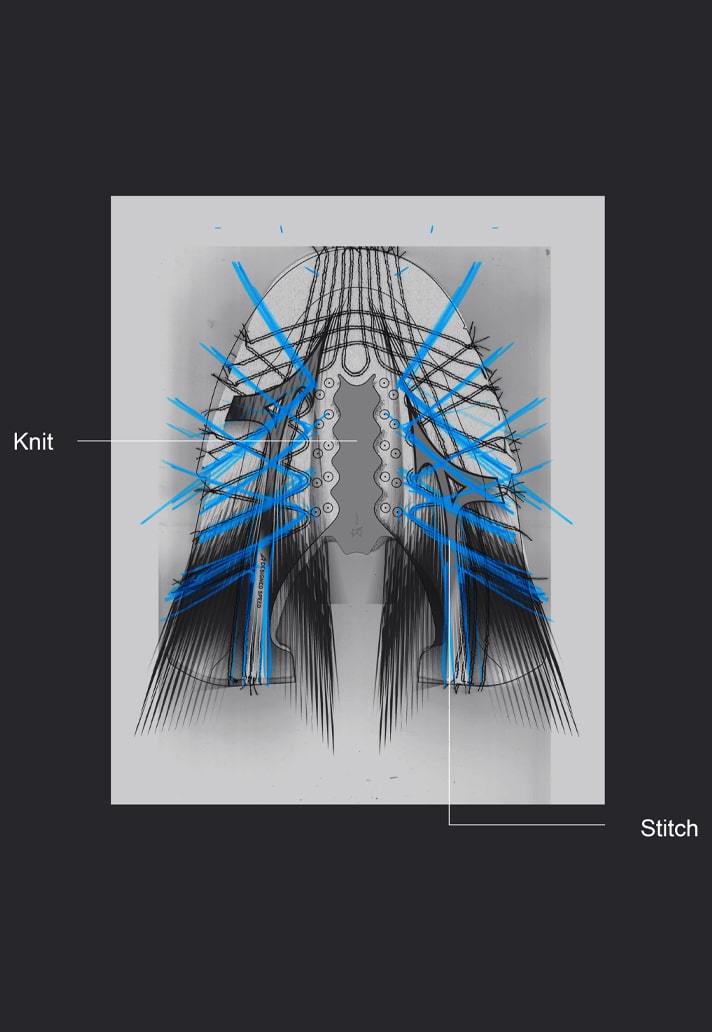

Mizuno Football has always been a performance-fitting brand. For every boot we create, material selection is driven by our pursuit of the ideal fit. With ALPHA III, we challenged ourselves by introducing a full-knit upper for the first time in this silo. In doing so, we wanted to prove that Mizuno can deliver its signature fit regardless of material. Our craftsmanship is central to that message, particularly through the original stitch pattern, which is unique to Mizuno. These stitches control stretch in the knit and ensure even tension during lasting. Materials may evolve, but craftsmanship remains at the heart of our identity.

You refer to the last as the soul of the shoe. What role did the Engineered Fit Last NEO play in shaping the Alpha III’s character, and how did it evolve during the design process?

Everything starts with the last. In 2020, when we updated the MORELIA II JAPAN, we developed the Engineered Fit Last to better match the modern footballer’s foot shape. That last is primarily used in flat-sole models like MORELIA II. For boots with external heel counters, such as MORELIA NEO and MIZUNO ALPHA, we apply the Engineered Fit Last NEO. With ALPHA III, we focused on designing an upper pattern that could fully express the potential of this last.

The stitchwork on the knit is subtle but purposeful. Can you talk us through the craft decisions that went into those details and what they unlock for the player?

ALPHA III features a one-piece full-knit upper. Unlike models such as MORELIA NEO, which use multiple materials, shaping a single-piece upper to the last is significantly more challenging. Achieving Mizuno Football’s signature fit under those conditions was our biggest obstacle. The stitch patterns were a key solution. They allowed us to control stretch and structure while maintaining flexibility. We tested dozens of stitch variations before finalising the design that best balanced fit, feel and performance.

Inside the boot, you’ve layered in ZEROGLIDE α Mesh to keep things tight without losing lightness. How do you balance those competing qualities when engineering the interior experience of a speed boot?

ZEROGLIDE α Mesh offers both lightness and grip. In ALPHA II, it was used extensively across the upper lining, including the tongue and heel. With ALPHA III’s full-knit construction, we introduced a suede lining in the heel to improve step-in comfort, while retaining ZEROGLIDE α Mesh in the forefoot. This allowed us to maintain grip and lightweight performance where it matters most.

The soleplate has roots in the MORELIA series, yet the Alpha III is its own creature entirely. Why did you decide to draw from that heritage, and how did you reinterpret it for a speed-focused design?

The outsole design remains consistent with the original ALPHA. Prior to ALPHA, Mizuno offered silos such as BASARA, IGNITUS and REBULA. During development, we revisited all of these, but ultimately found the strongest foundation in the highly regarded MORELIA NEO stud layout. From there, we added aggressive α triangular studs to enhance speed and traction. The result is a soleplate that blends tradition with innovation, and one that has been praised by many athletes.

KaRVO in the insole board adds snap and reduces energy loss. At what stage in the design cycle do you start to experiment with that kind of underfoot technology, and how do you test what “speed” feels like in practice?

KaRVO has been tested from the earliest prototype stages, combining qualitative feedback from contracted athletes with quantitative in-house evaluations. The original ALPHA featured a 1.2mm KaRVO plate. For ALPHA II, this was redesigned to a thinner 0.9mm version to improve lightness and rebound, without compromising responsiveness.

"We wanted to prove that Mizuno can deliver its signature fit regardless of material. Our craftsmanship is central to that message, particularly through the original stitch pattern of the full-knit upper, which is unique to Mizuno."

MIZUNO ENERZY in the heel and the ENERZY XP sockliner bring a softer, more cushioned side to a traditionally aggressive category. Why did it matter to introduce that comfort into a boot built for acceleration?

The modern game places unprecedented physical demands on players, and we believe performance technology should support that reality. The MIZUNO ENERZY XP sockliner delivers an exceptional balance of softness, rebound and lightness. We’re confident it helps players sustain high performance through intense workloads. In fact, some athletes were so impressed during testing that they continued using the ENERZY XP sockliner even while wearing ALPHA II.

João Félix spoke about the Alpha III moving with him, almost intuitively. How much of that response is intentional, and how much is the result of all the small engineering decisions coming together?

João genuinely loves ALPHA III. When we first met him, ALPHA II hadn’t yet launched. His positive feedback on ALPHA II helped establish our partnership, but by that point ALPHA III was already well into development. João tested early prototypes and rated the full-knit ALPHA III even higher than ALPHA II. That endorsement gave us the confidence to move forward decisively.

Every new generation is also a statement of philosophy. When you look at the Alpha III, what do you feel it says about Mizuno’s future in football?

Many people may not have expected Mizuno to release a full-knit football boot. We hope that surprise feels like a positive leap forward, a signal that new possibilities lie ahead for Mizuno Football.

Finally, if there’s one detail in the boot that might go unnoticed but means the most to you personally, what is it — and why?

If I had to choose one detail, it would be the silhouette. Creating a beautiful shape with a one-piece knit upper while achieving a perfect fit is extremely difficult. Yet ALPHA III expresses the soul of the Engineered Fit Last NEO in a way that feels natural and elegant. That balance is something only Mizuno Football can deliver. We will continue to pursue craftsmanship with integrity and bring excitement to players around the world through our products.

Shop the Mizuno Alpha III at prodirectsport.com/soccer